Why Tungsten Carbide Is Widely Used As Tool Material

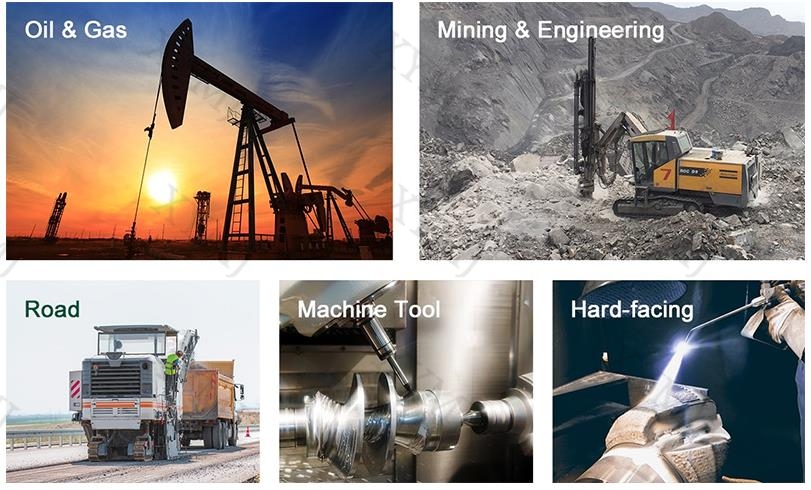

The advancement of technology in metallurgy, petroleum drilling, mining tools, and the rapid development of nuclear energy, has greatly increased the demand for high-quality and high-stability tungsten carbide parts and carbide products. Cemented carbide is used in more and more industries as the tool material.

What is tungsten carbide?

Tungsten carbide is an alloy material made of hard compounds which are consist of refractory metals and bonding metals, through powder metallurgy.

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remains basically unchanged even at a temperature of 500°C. It still has high hardness at 1000°C.

The development history of tungsten carbide

In 1923, Schroeter who is from Germany added 10% to 20% of cobalt to tungsten carbide powder as a binder and invented a new alloy of tungsten carbide and cobalt. The hardness is second only to diamond, which is the first artificially made first cemented carbide in the world. When cutting steel with a tool made of this alloy, the cutting edge will wear out quickly, and even the cutting edge may crack. In 1929, Schwarzkov, from the United States, added a certain amount of compound carbide of tungsten carbide and titanium carbide to the original composition for improving the performance of the tool in cutting steel. This is another achievement in the development history of tungsten carbide.

In the past two decades, coated cemented carbide has also come out. In 1969, Sweden successfully developed a titanium carbide-coated tool. The matrix of the tool is tungsten-titanium-cobalt cemented carbide or tungsten-cobalt cemented carbide. The thickness of the surface titanium carbide coating is only a few microns, but compared with the alloy tools of the same brand, The service life is extended by 3 times, and the cutting speed is increased by 25% to 50%. The fourth generation of coated tools appeared in the 1970s, which can be used to cut difficult-to-process materials.

Wide applications of tungsten carbide

Tungsten carbide is widely used as tool materials, such as turning tools, milling cutters, planers, drills, boring cutters, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, and can also be applied for cutting hard-to-process materials such as heat-resistant steel, stainless steel, high manganese steel, tool steel, etc. It is used to manufacturing cutting tools, cobalt tools and wear-resistant parts, and is widely applicable in the military industry, aerospace, mechanical processing, metallurgy, petroleum drilling, mining tools, electronic communications, and other much more fields.

The classification of tungsten carbide

Classified by composition

Tungsten Cobalt Cemented Carbide

The main components are tungsten carbide (WC) and binder cobalt (Co).

The grade is composed of “YG” and the percentage of the average cobalt content. For example, YG8 means that the average WCo=8%, and the rest is tungsten-cobalt cemented carbide.

General tungsten-cobalt alloys are mainly used in carbide tools, molds and geological products.

Tungsten Titanium Cobalt Cemented Carbide

The main components are tungsten carbide, titanium carbide (TiC) and cobalt. The grade consists of “YT” and the percentage of the average content of titanium carbide. For example, YT15 means that the average TiC=15% and the rest is tungsten carbide and cobalt.

Tungsten Titanium Tantalum (niobium) Carbide

The main components are tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of cemented carbide is also called general cemented carbide or universal cemented carbide.

Its grade name is composed of “YW” with a sequence number, such as YW1.

Classified by shape

Spheroid

Tungsten carbide balls are mainly composed of high-hardness, refractory metal carbide (WC, TiC) micron powders. Commonly cemented carbides include YG, YN, YT, and YW series.

The commonly used carbide balls are mainly including grades of YG6, YG6x, YG8, YG13, YG20, YN6, YN12, YT5, YT15.

Rod

The main characteristics of carbide rods are stable mechanical properties, easy welding, high wear resistance and high impact resistance.

Advantages

- Good wear resistance;

- Good corrosion resistance;

- High toughness;

- Extrusion method and HIP sintering.

Applications

Tungsten carbide rods are mainly used for drills, end mills, and reamers. It can also be applicable for cutting, stamping and measuring tools. It is used in papermaking, packaging, printing, and non-ferrous metal processing industries. In addition, it is also widely suitable to process high-speed steel tools, cemented carbide milling cutters, carbide cutters, NAS cutting tools, aviation tools, carbide drill bits, milling cutter core bits, tapered milling cutters, metric milling cutter, micro end milling cutter, reaming pilot, electronic cutter, step drill, metal cutting, rotary file, etc.

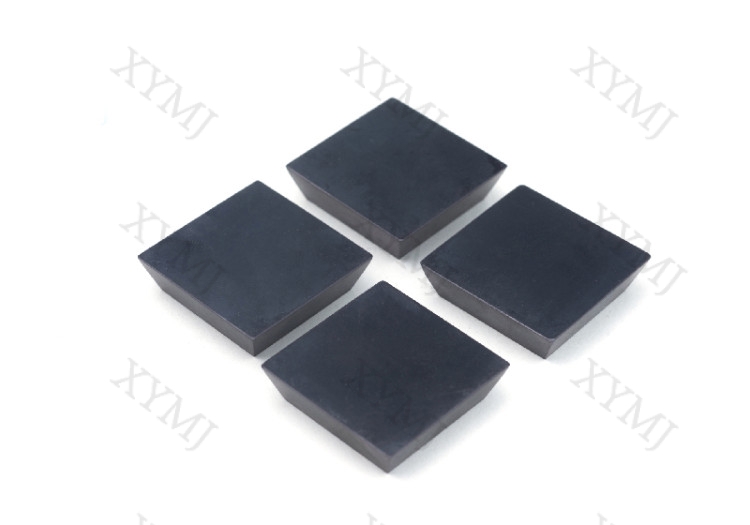

Plate

The carbide plate has good durability and strong impact resistance and can be used in hardware and standard stamping dies.

Professional tungsten carbide manufacturer – XYMJ

XYMJ, which is the abbreviation of Zigong Xingyu Cemented Carbide Dies&Tools Co., Ltd is a professional carbide manufacturer with more than 20 years of experience in the custom production of various kinds of carbide parts. The company has more than 10,000 square meters of standardized factory and office buildings in Bancang Industrial Zone, Zigong City, Sichuan Province.

XYMJ has a high-quality team, full coverage of material experts, designers, engineers, front-line technicians and after-sales technical teams.

Main products from XYMJ

- Carbide non-standard mold shells: cold stamping molds, battery molds, cemented carbide molds, drawing mold shells, etc.

- Tungsten carbide wear parts: carbide valve core, carbide valve seat, carbide ball, carbide roller, etc

- Cemented carbide products: carbide plates, carbide strips, carbide rod, etc.

- Powder metallurgical molds: gear molds, sizing molds, auto parts, motor-driven mold parts.

- Carbide tools: cutting tools, special mining tools.

Summary

Tungsten carbide has high hardness, high strength, excellent wear resistance and corrosion resistance and has been widely used in various industries. It will become more and more important tool materials with its high performance. XYMJ is one of the leading carbide manufacturers in China, which can provide custom carbide parts, OEM & ODM available.