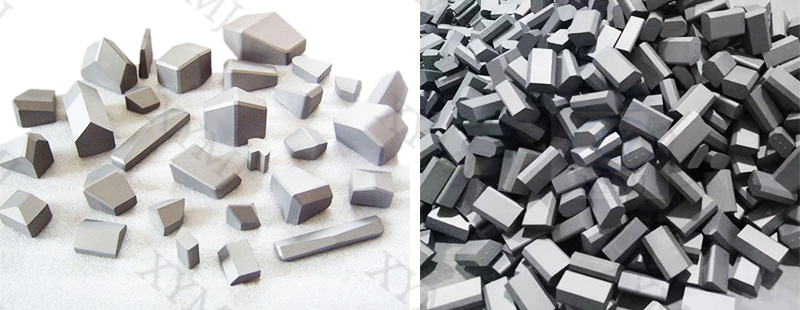

Why Choose Tungsten Carbide Mining Tips/Cutter

The carbide mining tips or cutter adopts high-performance alloy inserts for alloy drills to effectively reduce chipping and keep excellent wear resistance. Multi-layer geometric cutting end edge to improve drainage performance and low cutting resistance, applied for a wide range of drilling rigs & machines.

Carbide tips are often used as drilling tools for coal shearers, mining machinery tools, and road maintenance tools for snow removal and road cleaning.

All of the tungsten carbide mining tips provided by XYMJ are made from virgin raw materials with advanced technology for high precison grinding and polishing. Various sizes and styles are available with customized service,

Grade List

| Grade | Typical physical properties | Performances & Applications

| ||

|

| Density (g/cm3) | TRS | Hardness (HRA) | |

| YG4C | 15.05 | 1790 | 90.8 | For inserting the electrical and compressed air drill bits, used d in geological prospecting, coal mining, suitable for drilling coal. |

| YG8 | 14.68 | 2240 | 89.7 | For electrical coal drill bits,coal cutting picks used in geological prospecting. |

| YG8C | 14.62 | 2350 | 88.1 | For rotary rock drill bits for medium-soft and medium-hard rock. |

| YG11C | 14.3 | 2410 | 87.1 | For tipping of bits of heavy rock drills and rotary hammer rock drills cutting hard rocks. |

| YG13C | 14.15 | 2700 | 86.7 | For making drill cones to drill hard and medium hard rock formation in the oil fields. |

| YG15 | 14.05 | 2300 | 88.0 | High intension, lower wear-resistance.Suitable for making bits used in rotary machines and heavy rotary machines. |

| YG15C | 14 | 2700 | 85.7 | For making drill cone to drill all kinds of rock formations |

Production Process