Requirements for Hard Alloys in Coalfield Geological Exploration

At the beginning of July, one of our middle east customer visited our factory and did the audit, The visit aimed to evaluate Zigong Xingyu’s production capabilities, quality control systems,…

Middle East Customer Did the Audit of Zigong Xingyu

At the beginning of July, one of our middle east customer visited our factory and did the audit, The visit aimed to evaluate Zigong Xingyu’s production capabilities, quality control systems,…

Why can carbide drawing dies completely replace steel dies?

For the drawing die itself, when processing the drawn product, it is mainly necessary to ensure its size and surface quality. The drawn products themselves are mostly steel and many…

“Warmly Welcoming Korean Clients and Signing Agreements on-Site to Launch a New Chapter of Cooperation”

On June 13, 2025, ZGXYMJ welcomed a distinguished group of guests: a delegation of Korean clients. Their visit represents a high level of recognition for our factory and an important opportunity for…

Tungsten carbide finishing machining Introduction

We all know that cemented carbide is an alloy material made by powder metallurgy process of hard compounds of refractory metals and bonding metals. An alloy composed of one or…

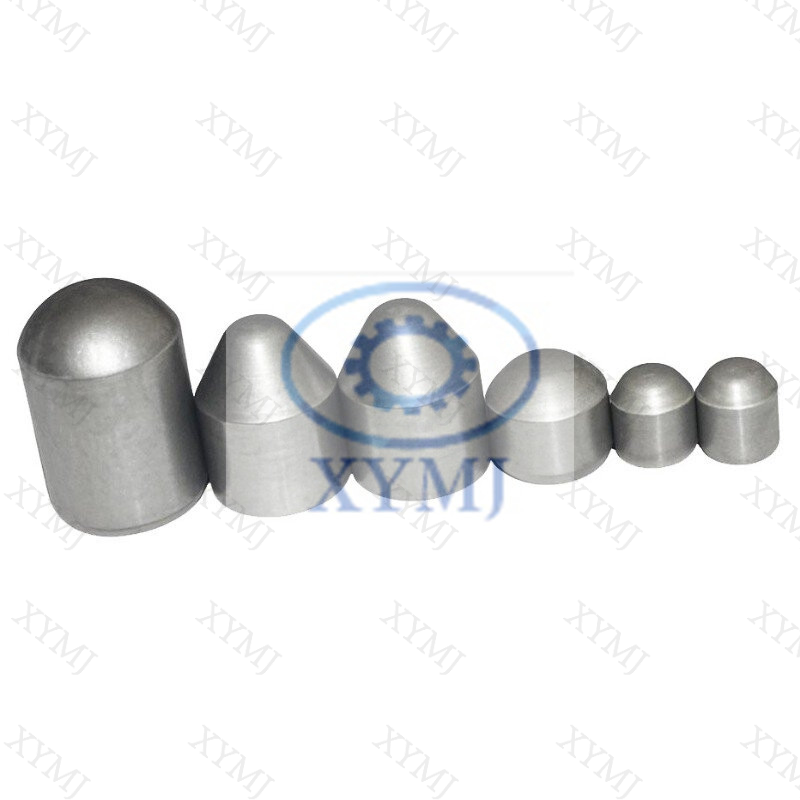

Application and Characteristics of Cemented Carbide Blanks

In the field of cemented carbide, common blank products usually include bars, strips, plates, etc. With tungsten carbide (WC) as the matrix and cobalt (Co) as the bonding phase, it…