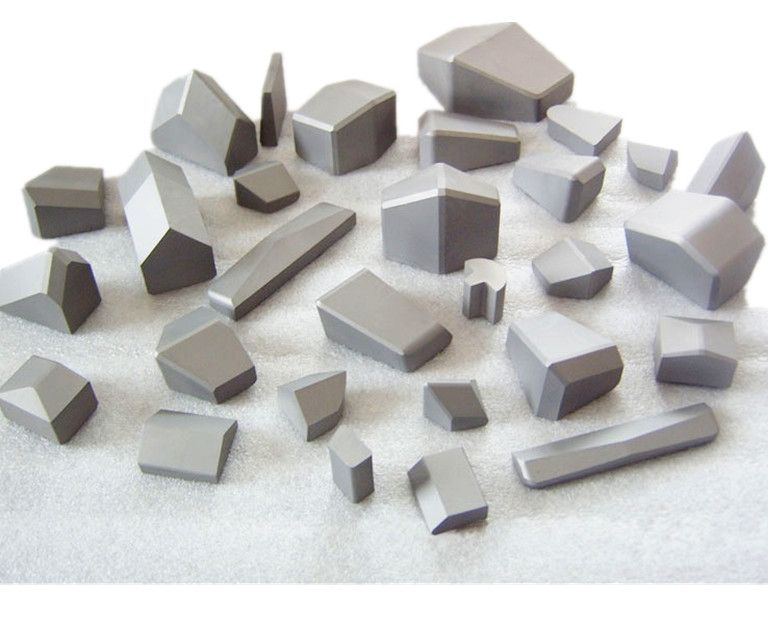

Cemented carbide advantages and disadvantages

Advantages

1. Excellent wear resistance: the main components of Cemented Carbide are carbide and metallic cobalt, which have very high hardness and can withstand abrasion at high temperature and high pressure, so they are widely used in the field of wear resistance, such as cutting tools, mining machinery and so on.

2. Excellent corrosion resistance: Cemented carbide has high corrosion resistance and can maintain good stability in corrosive media such as acid, alkali and salt.

3. Good high temperature stability: Cemented carbide can still maintain good hardness, rigidity and wear resistance under high temperature environment, which is an excellent high temperature material.

Disadvantages of Cemented Carbide

1. Higher cost: The main components of Cemented Carbide are tungsten, tungsten cobalt and other high cost materials, which are more expensive to produce .

2. Easy to break: Cemented carbide has the characteristics of high hardness and brittleness, once impacted by external force, it is easy to break.

3. Difficult to process: Because Cemented Carbide has high hardness, it is also difficult to process, which requires special cutting method and complicated production process.